| SKU | Mill Diameter (mm) | Ball Nose Radius (mm) | Overall length (mm) | Shank diameter (mm) | Flutes | Length of cut (mm) | Stock | Price | Qty | Add |

|---|---|---|---|---|---|---|---|---|---|---|

| GM876010 | 1.0 | R0.5 | 38.0 | 3.0 | 2 | 3.0 | 5 days | - | ||

| GM876020 | 2.0 | R1.0 | 50.0 | 6.0 | 2 | 3.0 | 5 days | - | ||

| GM876030 | 3.0 | R1.5 | 50.0 | 6.0 | 2 | 4.0 | 5 days | - | ||

| GM876040 | 4.0 | R2.0 | 54.0 | 6.0 | 2 | 5.0 | 5 days | - | ||

| GM876060 | 6.0 | R.3.0 | 54.0 | 6.0 | 2 | 7.0 | In stock | $50.00 | ||

| GM876080 | 8.0 | R4.0 | 58.0 | 8.0 | 2 | 9.0 | In stock | $80.00 | ||

| GM876100 | 10.0 | R5.0 | 66.0 | 10.0 | 2 | 11.0 | In stock | $125.10 | ||

| GM876120 | 12.0 | R6.0 | 73.0 | 12.0 | 2 | 12.0 | 5 days | - | ||

| GM876160 | 16.0 | R8.0 | 82.0 | 16.0 | 2 | 16.0 | Low stock | $247.90 |

Add X-POWER 2 Flute 30°Helix Short Ball End Mill (GM876) to comparison

View Comparison- Overview

- Operation

- Work Material

- Speeds & Feeds

- Reviews

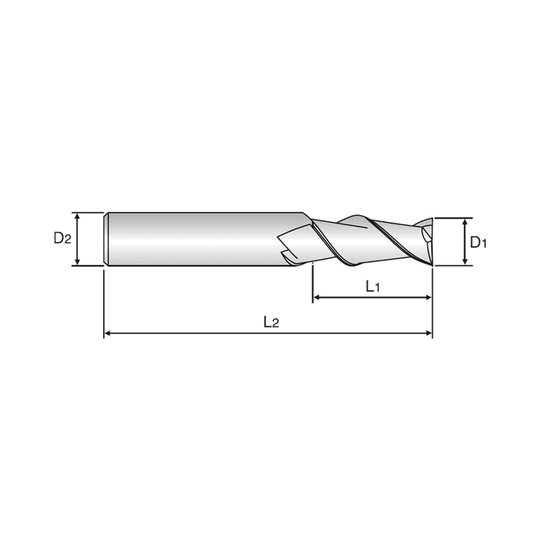

X-POWER 2 Flute 30° Helix Short Ball End Mill GM876 delivers accurate contouring in steels and cast iron. Advanced ‘Z Coating’ with an ultrafine micrograin carbide substrate supports long tool life in wet or dry cutting. It handles stainless steel and hardened steels to 55 Rockwell with stable, clean finishes. Diameters span 1–16 mm, with 20–30% longer life and over 20% faster cutting.

Specifications

| Flutes | 2 |

| Helix Angle | 30° |

| Cutting Edge Shape | BALL NOSE |

| Size Min | R0.5 |

| Size Max | R8.0 |

| Length |

Short Length |

| Coating | Y-Coating |

- 2 flute 30° helix ball nose for precise 3D contouring and pocketing

- Advanced ‘Z Coating’ with ultrafine micrograin carbide substrate extends tool life

- Performs in steels hardened steels to 55 Rockwell stainless steel and cast iron

- Reliable wet or dry cutting for flexible process setup

- Short length improves rigidity and dimensional control in shallow features

- 1–16 mm diameter range with over 20% faster cutting and improved finish

| Workpiece Material | P K H |

| Ball Radius Tolerance | 0.02 |

| Cutting Shape | Ball Nose |

| Hardened Steels(HRc40~45) | Excellent |

| Helix Angle | Ball Nose 30 |

| No. Flutes | 2 |

| Operation | Profiling, Side Milling, Small Part |

| Shank Type | Plain |

| Surface Treatment | YG-1 Y Coating |

| Tool Material | Carbide |

Great

Excellent

Excellent

Great

Excellent

Great

Great

Speeds & Feeds

| MATERIAL | P | K | ||||||||||||||

| NON-ALLOYED STEELS ALLOY STEELS | ALLOY STEELS HEAT RESISTANT STEELS | HARDENED STEELS | CAST IRON | |||||||||||||

| HARDNESS | ~HRc30 | HRc30~HRc40 | HRc45~HRc55 | |||||||||||||

| STRENGTH | ~1000N/mm2 | 1000 ~ 1250N/mm2 | 1500 ~ 2000N/mm2 | |||||||||||||

| DIAMETER | RPM | FEED | Vc | Fz | RPM | FEED | Vc | Fz | RPM | FEED | Vc | Fz | RPM | FEED | Vc | Fz |

| R0.5 × 1.0 | 17650 | 280 | 55 | 0.008 | 14250 | 225 | 45 | 0.008 | 6500 | 100 | 20 | 0.008 | 17490 | 280 | 55 | 0.008 |

| R0.75 × 1.5 | 17650 | 390 | 85 | 0.011 | 13600 | 300 | 65 | 0.011 | 5960 | 135 | 30 | 0.011 | 17490 | 390 | 80 | 0.011 |

| R1.0 × 2.0 | 16130 | 840 | 100 | 0.026 | 11980 | 550 | 75 | 0.023 | 5240 | 170 | 35 | 0.016 | 15980 | 835 | 100 | 0.026 |

| R1.25 × 2.5 | 16130 | 840 | 125 | 0.026 | 11980 | 550 | 95 | 0.023 | 5240 | 170 | 40 | 0.016 | 15980 | 835 | 125 | 0.026 |

| R1.5 × 3.0 | 14670 | 760 | 140 | 0.026 | 11200 | 515 | 105 | 0.023 | 5060 | 170 | 50 | 0.017 | 14540 | 755 | 135 | 0.026 |

| R2.0 × 4.0 | 11760 | 830 | 150 | 0.035 | 9410 | 595 | 120 | 0.032 | 4700 | 200 | 60 | 0.021 | 11660 | 820 | 145 | 0.035 |

| R2.5 × 5.0 | 10240 | 920 | 160 | 0.045 | 8180 | 650 | 130 | 0.040 | 4120 | 200 | 65 | 0.024 | 10150 | 910 | 160 | 0.045 |

| R3.0 × 6.0 | 9510 | 1140 | 180 | 0.060 | 7730 | 930 | 145 | 0.060 | 3560 | 215 | 65 | 0.030 | 9420 | 1130 | 180 | 0.060 |

| R4.0 × 8.0 | 8020 | 1445 | 200 | 0.090 | 6460 | 1030 | 160 | 0.080 | 2770 | 245 | 70 | 0.044 | 7950 | 1430 | 200 | 0.090 |

| R5.0 × 10.0 | 7130 | 1715 | 225 | 0.120 | 5700 | 1140 | 180 | 0.100 | 2280 | 250 | 70 | 0.055 | 7070 | 1700 | 220 | 0.120 |

| R6.0 × 12.0 | 6540 | 1960 | 245 | 0.150 | 5200 | 1245 | 195 | 0.120 | 1960 | 275 | 75 | 0.070 | 6480 | 1945 | 245 | 0.150 |

| R8.0 × 16.0 | 5340 | 1925 | 270 | 0.180 | 4230 | 1185 | 215 | 0.140 | 1510 | 275 | 75 | 0.091 | 5290 | 1910 | 265 | 0.181 |

| R10.0 × 20.0 | 4640 | 1860 | 290 | 0.200 | 3650 | 1165 | 230 | 0.160 | 1240 | 280 | 80 | 0.113 | 4600 | 1845 | 290 | 0.201 |

| RPM: | – | rev/min |

| FEED: | – | mm/min |

| Vc: | – | m/min |

| Fz: | – | mm/tooth |