| SKU | Mill Diameter (mm) | Corner Radius (mm) | Overall length (mm) | Shank dia. (mm) | Length of cut (mm) | Length below shank (mm) | Neck dia. (mm) | Stock | Price | Qty | Add |

|---|---|---|---|---|---|---|---|---|---|---|---|

| EI99600200000 | 0.2 | - | 40.0 | 3.0 | 0.3 | - | - | 5 days | $140.80 | ||

| EI99600300000 | 0.3 | - | 40.0 | 3.0 | 0.5 | - | - | 5 days | $121.40 | ||

| EI99600400000 | 0.4 | - | 40.0 | 3.0 | 0.6 | - | - | 5 days | $112.50 | ||

| EI99600505025 | 0.5 | R0.05 | 40.0 | 3.0 | 0.7 | 2.5 | 0.45 | 5 days | $118.10 | ||

| EI99600605050 | 0.6 | R0.05 | 40.0 | 3.0 | 0.9 | 5.0 | 0.55 | 5 days | $112.50 | ||

| EI99600805070 | 0.8 | R0.05 | 40.0 | 3.0 | 1.2 | 7.0 | 0.75 | 5 days | $107.30 | ||

| EI99601010120 | 1 | R0.1 | 40.0 | 3.0 | 1.5 | 12.0 | 0.95 | 5 days | $100.50 | ||

| EI99601210100 | 1.2 | R0.1 | 50.0 | 3.0 | 1.8 | 10.0 | 1.15 | 5 days | $100.90 | ||

| EI99601515180 | 1.5 | R0.15 | 50.0 | 3.0 | 2.2 | 18.0 | 1.4 | 5 days | $105.80 | ||

| EI99602015250 | 2 | R0.15 | 60.0 | 3.0 | 2.2 | 25.0 | 1.9 | 5 days | $111.10 | ||

| EI99603020100 | 3 | R0.2 | 65.0 | 4.0 | 3.0 | 10.0 | 2.9 | 5 days | $126.30 | ||

| EI99604020200 | 4 | R0.2 | 65.0 | 6.0 | 4.0 | 20.0 | 3.9 | 5 days | $155.90 | ||

| EI99605030200 | 5 | R0.3 | 75.0 | 6.0 | 5.0 | 20.0 | 4.9 | 5 days | $155.90 | ||

| EI99606030300 | 6 | R0.3 | 75.0 | 6.0 | 6.0 | 30.0 | 5.9 | 5 days | $167.10 |

Add (EI996) D-Power Carbide 2Flute Corner Radius End Mill, Miniature Neck for Graphite (Diamond Coated) to comparison

View Comparison- Overview

- Specifications

- Specifications

- Operation

- Work Material

- Reviews

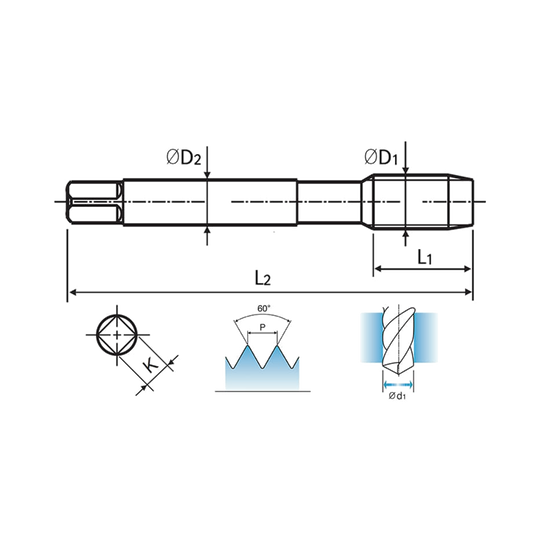

The YG-1 EI996 series D-Power diamond coated micrograin carbide cutters has 2 flutes and a plain shank. These slot drills have a reduced neck and corner radius for increased wear resistance. These range in diameter from 0.2mm-6mm. The D-Power range is the first choice for the high performance machining of graphite. It is also suitable for machining abrasive aluminium, plastics, brass, copper, CFRP and GFRP composites.

- First choice for high performance machining of graphite with extreme wear resistance.

- Excellent performance in abrasive non-ferrous materials.

- Diamond coating has high lubricity and low coefficient of friction, preventing the tool from fast wear common in abrasive material machining.

- Reduced neck for deep pocket machining.

- Suitable for high accuracy machining.

- Smooth and excellent surface finish on graphite.

- Also suitable for high speed machining of Wrought Aluminium, Bakelite, Plastics, Wood, Brass and non-ferrous metals.

| Workpiece Material | N |

| Cutting Shape | Corner Radius |

| Graphite | Excellent |

| No. Flutes | 3 |

| Operation | Die Sinking, Facing, Side Milling, Slotting, Small Part |

| Shank Type | Plain |

| Surface Treatment | Diamond Coating |

| Tool Material | Carbide |

| Flutes | 2 |

| Helix Angle | 30° |

| Cutting Edge Shape | CORNER RADIUS |

| Size Min | D0.2 |

| Size Max | D6.0 |

| Length |

MINIATURE NECK |

| Coating | Diamond |