| SKU | Size | TPI | Thread length (mm) | Overall length (mm) | Neck length (mm) | Shank dia. (mm) | Square size (mm) | Square length (mm) | Flutes | Tapping drill dia. (mm) | Stock | Price | Qty | Add |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TB904162 | #4 | 40UNC | 6.0 | 56.0 | 18.0 | 3.5 | 2.7 | 6.0 | 3 | 2.3 | 5 days | - | ||

| TB904202 | #5 | 40UNC | 7.0 | 56.0 | 18.0 | 3.5 | 2.7 | 6.0 | 3 | 2.6 | 5 days | $22.30 | ||

| TB904242 | #6 | 32UNC | 7.0 | 56.0 | 20.0 | 4.0 | 3.0 | 6.0 | 3 | 2.85 | 5 days | - | ||

| TB904322 | #10 | 24UNC | 10.0 | 70.0 | 25.0 | 6.0 | 4.9 | 8.0 | 3 | 3.9 | 5 days | $23.00 | ||

| TB904402 | 1/4 | 20UNC | 13.0 | 80.0 | 30.0 | 7.0 | 5.5 | 8.0 | 3 | 5.2 | In stock | $30.60 | ||

| TB904442 | 5/16 | 18UNC | 14.0 | 90.0 | 35.0 | 8.0 | 6.2 | 9.0 | 3 | 6.6 | In stock | $36.70 | ||

| TB904482 | 3/8 | 16UNC | 16.0 | 100.0 | 39.0 | 9.0 | 7.0 | 10.0 | 3 | 8.0 | In stock | $44.10 | ||

| TB904522 | 7/16 | 14UNC | 17.0 | 100.0 | 40.0 | 8.0 | 6.2 | 9.0 | 3 | 9.4 | In stock | $62.40 | ||

| TB904642 | 5/8 | 11UNC | 22.0 | 110.0 | 44.0 | 12.0 | 9.0 | 12.0 | 3 | 13.5 | In stock | $94.80 | ||

| TB904702 | 3/4 | 10UNC | 25.0 | 125.0 | 50.0 | 14.0 | 11.0 | 14.0 | 4 | 16.5 | In stock | $115.10 | ||

| TB904782 | 1 | 8UNC | 30.0 | 160.0 | 60.0 | 20.0 | 16.0 | 16.0 | 4 | 22.25 | Low stock | $189.20 |

Add (TB904) HSS-E (M35) UNC Spiral Flute for Stainless Steel to comparison

View Comparison- Overview

- Specifications

- Operation

- Work Material

- Reviews

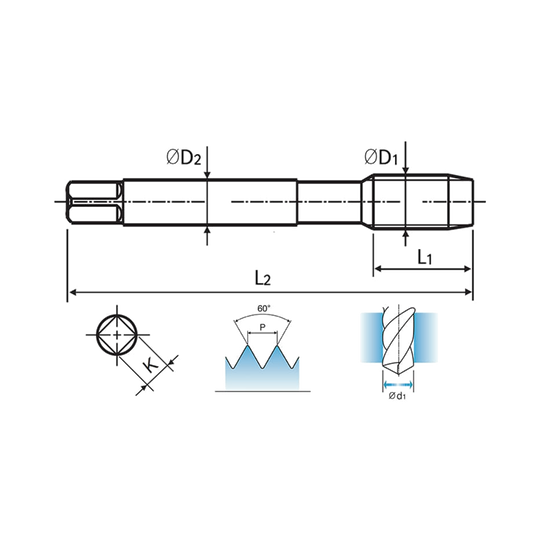

The YG-1 TB904 Series 1/2 x 13TPI UNC Spiral Flute Tap delivers high performance in stainless steel and other tough alloys. Constructed from HSS-E (M35) with 5% cobalt, it offers exceptional heat resistance and durability. The VAP surface treatment reduces friction, while the spiral flute geometry ensures smooth chip evacuation in blind holes, preventing overfeeding and early wear.

- HSS-E (M35) with 5% cobalt for durability and heat resistance

- VAP surface finish minimises friction and galling

- Spiral flute geometry ideal for blind hole tapping

- Designed for stainless steel, titanium, and nickel alloys

- Patented design prevents overfeeding and tap failure

| Workpiece Material | P M |

| Helix Angle | Square 40 |

| Operation | Blind Drilling |

| Surface Treatment | Steam Oxide Coating |

| Thread Angle | 60 |

| Thread Class | 2B |

| Thread Form | C |

| Thread Shape | UNC |

| Tool Material | HSS-E |

| Tool Standard | DIN 371-376 |

Great

Great

Great

Excellent

No VDI recommendations set for this product.