Add i-Xmill Corner Radius Insert for General Purpose End Mill (XMR110A) to comparison

View Comparison- Overview

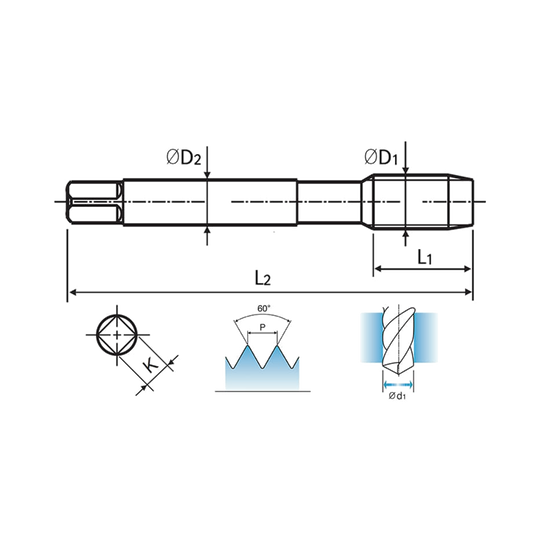

- Specifications

- Specifications

- Operation

- Work Material

- Speeds & Feeds

- Reviews

- The optimum geometry of the tool to achieve the better reliability and less vibration and cutting load.

- Interchangeability with i-Xmill ball holder, but the precise cutting is possible with i-Xmill corner radius holder due to higher stability and strength of tool.

- The various and wide cutting range makes it possible to machine over the roughing and finishing.

- Special coating makes high hardness with high thermal stability against oxidation.

| Workpiece Material | P M |

| Corner Radius Tolerance | 0.015 |

| Cutting Shape | Roughing |

| No. Flutes | 2 |

| Operation | Facing, Side Milling, Small Part |

| Surface Treatment | Aluminium Titanium Nitride Coating |

| Tool Material | NG HM |

| Flutes | 2 |

| Helix Angle | - |

| Cutting Edge Shape | CORNER RADIUS |

| Size Min | D8.0 |

| Size Max | D33.0 |

| Length | - |

| Coating | AlTiN |

Excellent

Excellent

Excellent

Excellent

No VDI recommendations set for this product.

Speeds & Feeds

| ISO | VDI 3323 |

Material Description | Parameter | Diameter (Ø) | ||||||

| 8 | 10, 11 | 12, 13 | 16, 17 | 20, 21 | 25, 26 | 30, 32, 33 | ||||

| P | 1-4 | Non-Alloy Steel | Vc | 160~300 | 160~300 | 160~300 | 160~300 | 160~300 | 160~300 | 160~300 |

| fz | 0.20~0.15 | 0.20~0.15 | 0.20~0.15 | 0.25~0.20 | 0.25~0.20 | 0.25~0.20 | 0.25~0.20 | |||

| RPM | 6370~11940 | 5090~9550 | 4240~7960 | 3180~5970 | 2550~4770 | 2040~3820 | 1700~3180 | |||

| FEED | 2550~3580 | 2040~2860 | 1700~2390 | 1590~2390 | 1270~1910 | 1020~1530 | 850~1270 | |||

| 5 | Vc | 120~280 | 120~280 | 120~280 | 120~280 | 120~280 | 120~280 | 120~280 | ||

| fz | 0.20~0.15 | 0.20~0.15 | 0.20~0.15 | 0.25~0.20 | 0.25~0.20 | 0.25~0.20 | 0.25~0.20 | |||

| RPM | 4770~11140 | 3820~8910 | 3180~7430 | 2390~5570 | 1910~4460 | 1530~3570 | 1270~2970 | |||

| FEED | 1910~3340 | 1530~2670 | 1270~2230 | 1190~2230 | 950~1780 | 760~1430 | 640~1190 | |||

| 6-7 | Low-Alloy Steel | Vc | 160~300 | 160~300 | 160~300 | 160~300 | 160~300 | 160~300 | 160~300 | |

| fz | 0.20~0.15 | 0.20~0.15 | 0.20~0.15 | 0.25~0.20 | 0.25~0.20 | 0.25~0.20 | 0.25~0.20 | |||

| RPM | 6370~11940 | 5090~9550 | 4240~7960 | 3180~5970 | 2550~4770 | 2040~3820 | 1700~3180 | |||

| FEED | 2550~3580 | 2040~2860 | 1700~2390 | 1590~2390 | 1270~1910 | 1020~1530 | 850~1270 | |||

| 8 | Vc | 120~280 | 120~280 | 120~280 | 120~280 | 120~280 | 120~280 | 120~280 | ||

| fz | 0.20~0.15 | 0.20~0.15 | 0.20~0.15 | 0.25~0.20 | 0.25~0.20 | 0.25~0.20 | 0.25~0.20 | |||

| RPM | 4770~11140 | 3820~8910 | 3180~7430 | 2390~5570 | 1910~4460 | 1530~3570 | 1270~2970 | |||

| FEED | 1910~3340 | 1530~2670 | 1270~2230 | 1190~2230 | 950~1780 | 760~1430 | 640~1190 | |||

| M | 12-14 | Stainless Steel | Vc | 90~130 | 90~130 | 90~130 | 90~130 | 90~130 | 90~130 | 90~130 |

| fz | 0.10~0.10 | 0.11~0.11 | 0.12~0.11 | 0.13~0.13 | 0.13~0.13 | 0.13~0.12 | 0.13~0.12 | |||

| RPM | 3580~5170 | 2860~4140 | 2390~3450 | 1790~2590 | 1430~2070 | 1150~1660 | 950~1380 | |||

| FEED | 720~1030 | 630~910 | 550~790 | 450~650 | 360~520 | 290~410 | 240~340 | |||

| RPM: | – | rev/min |

| FEED: | – | mm/min |

| Vc: | – | m/min |

| Fz: | – | mm/tooth |